Construction site safety inspection is vital to ensure projects meet safety standards, building codes, and quality control requirements. These inspections, conducted throughout the building process, involve a comprehensive evaluation of various aspects, including structural elements, safety protocols, and regulatory compliance. By identifying potential issues early on, job site inspections help mitigate risks and maintain high workmanship standards.

The importance of construction site safety cannot be overstated. According to OSHA, in 2020, one in five worker deaths occurred in the construction industry. This alarming statistic highlights the critical need for routine safety inspections to prevent accidents and ensure worker well-being.

Construction site safety inspection can protect workers, and also have positive financial impacts on construction firms. Studies show that companies with robust safety programs experience greater financial benefits.

A well-structured checklist is essential for identifying and addressing potential hazards on construction sites. Covering key safety areas, this checklist serves as a guide to ensure worker well-being and reduce the likelihood of accidents.

Here’s a closer look at the top 5 components of a construction site safety inspection checklist that you must ensure.

Here’s Your Must-Have Construction Site Safety Inspection Checklist

1.Site security

Before any construction work begins, it’s crucial to establish a safe and organized work environment. This starts with meticulous site preparation. Think of it as setting the stage for a successful performance – every element needs to be in its right place.

Clear Access Routes: Ensure smooth and unobstructed pathways for vehicles and workers to prevent collisions and facilitate efficient movement.

Strategic Material Storage: Properly store construction materials to avoid creating hazards. Keep materials organized and secure to prevent trips, falls, and material collapses.

Informative Signage: Use clear and visible signage to communicate potential hazards, safety instructions, and emergency procedures.

Protective Barriers: Erect barriers and guardrails around hazardous areas like excavations, floor openings, and elevated platforms to prevent falls.

By prioritizing site preparation and organization, you create a solid foundation for a safe and productive construction project. A well-maintained site reduces the risk of accidents and saves you trouble in case of a surprise construction site safety inspection.

2. Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a worker’s first line of defense against potential hazards. Think of it as a suit of armor designed to shield against specific risks. This checklist item emphasizes the critical importance of ensuring:

Availability: Is the necessary PPE readily available for every worker on site? This includes essentials like hard hats, safety goggles, high-visibility vests, gloves, and protective footwear.

Condition: Regularly inspect PPE to ensure it’s in good working order. Damaged or worn-out equipment won’t provide adequate protection. Look for cracks in hard hats, tears in gloves, and wear and tear on safety footwear.

Proper Usage: PPE is only effective if worn correctly. Ensure workers understand how to properly wear and use their PPE and enforce its consistent use across the site.

Key Questions to Ask:

- Are all workers wearing the appropriate PPE for their specific tasks?

- Has the correct gear been distributed to all workers?

- Is each piece of equipment in good repair?

3. Electrical safety

Construction sites are buzzing with electrical activity, and with that comes the potential for serious hazards. This checklist item focuses on mitigating electrical risks through:

Proper Installation: Ensure all electrical wiring, outlets, and equipment are installed according to code and industry best practices. Look for any exposed wires, damaged cords, or overloaded circuits.

Grounding: Verify that all electrical systems are properly grounded to prevent electrical shocks. Grounding provides a safe path for electricity to flow in case of a fault.

Circuit Protection: Inspect circuit breakers and fuses to ensure they are the correct size and in good working order. These devices protect against overloads and short circuits that can cause fires.

Lockout/Tagout Procedures: Enforce strict lockout/tagout procedures whenever working on electrical equipment. This involves de-energizing the equipment and using locks and tags to prevent accidental re-energization.

4. Safety communication

A construction site safety inspection doesn’t involve analysing just physical precautions; it’s also about clear communication and a shared understanding of safety protocols. This checklist item focuses on two key aspects:

Hazard Communication

Clear Labelling: Ensure all hazardous materials are clearly labelled with appropriate warnings, pictograms, and identification information. This includes chemicals, solvents, paints, and other potentially harmful substances.

Accessible Safety Data Sheets (SDS): Provide workers with easy access to Safety Data Sheets (SDS) for all hazardous materials on site. SDSs contain detailed information about the hazards, safe handling procedures, and emergency response measures for each substance.

Safety Policies

Effective Communication Systems: Establish clear communication channels for disseminating safety information. This includes regular safety meetings, toolbox talks, notice boards, and digital platforms for sharing updates and alerts.

Well-Defined Safety Policies: Develop and implement comprehensive safety policies that outline specific procedures, responsibilities, and expectations for all workers. These policies should cover topics like PPE use, hazard reporting, emergency procedures, and disciplinary actions for safety violations.

Threat escalation access: Ensure workers have access to immediate threat escalation in case of an emergency. A lone worker safety app can be used to trigger an alarm.

Managers can also set up customized, proactive safety checks that monitor and detect potential threats. If a threat is detected, the app automatically escalates the situation to the back-office via IVR, SMS, and/or email. Alerts include critical details such as the employee’s location and the nearest emergency response number, ensuring swift and effective assistance.

5. Equipment & Tool Safety

Construction relies heavily on tools and equipment, but these powerful assets can quickly turn into hazards if not properly used. This checklist item emphasizes the importance of:

Regular Inspections: Implement a strict schedule for inspecting all tools and equipment. This includes everything from hand tools and power tools to heavy machinery, scaffolding, and ladders. Look for signs of wear and tear, damage, and any defects that could compromise safety.

Maintenance: Ensure that all tools and equipment are properly maintained and serviced according to manufacturer recommendations. This includes regular cleaning, lubrication, and replacement of worn parts.

Safety Training: Provide comprehensive training to workers on the safe use and operation of all tools, equipment and even the worker safety app. This training should cover proper handling techniques, safety precautions, and emergency procedures.

Guarding and Safety Features: Verify that all machinery and equipment have the necessary guards and safety features in place and that they are functioning correctly.

Focus on these key areas:

Power Tools: Inspect cords, plugs, and switches for damage. Ensure safety guards are in place and functioning.

Ladders: Check for stability, rung condition, and locking mechanisms.

Scaffolding: Inspect for structural integrity, proper assembly, and secure footing.

Heavy Machinery: Ensure operators are trained and certified. Verify that safety features like emergency stops and warning signals are working correctly.

Conclusion

Ensuring a safe work environment is paramount , and conducting regular construction site safety inspection is crucial to achieving this goal. A well-structured walkthrough inspection checklist serves as a roadmap for identifying and mitigating potential hazards. It helps strengthen safety protocols and promotes a secure, productive construction site.

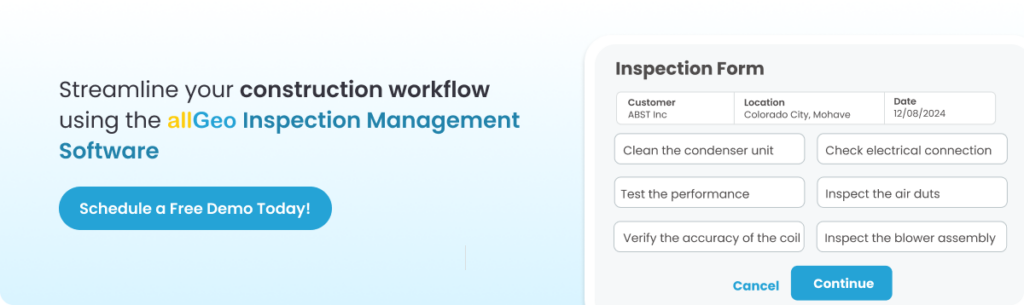

Moving away from paper-based safety management to digital tools can significantly benefit your safety inspection. Paper forms are notorious for getting lost, being difficult to read, and requiring tedious manual data entry.

By adopting a digital checklist, you gain a clear, real-time view of safety practices across all your sites. Workers can easily access vital safety information from any location using their mobile devices. This shift empowers your team with the knowledge they need to stay safe and productive.